Microkit |

Quadrature encoder principle |

|||||||||||||||

H7001 encodersThe H7001 is encapsulated in a light emitting diode package, but

the chip is on the flat side, and not on the lens side.

The H7001 is packaged in two different ways, depending on if the photodiode line matches vertical slots, as in the next figure, or horizontal slots. There are color marks, but the best way is to look at the orientation of the tags. Pay attention, the electrical pinout is different for the H7001H (see below).

|

Electrical specifications |

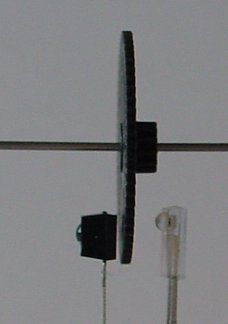

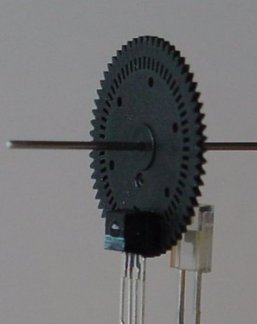

AssemblingThe H7001 must be as close as possible from the slotted disk. The

photodiode is preferably an IR led with a small angle, at a distance

and position that will illuminate the two slots in front of the

H7001. We developed specially the G3360 and G348 slotted gears to

make microrobot applications easy. Having the encoder directly on

the motor axis is possible, but one should check the maximum frequency

of signals, according to the microcontroller program, since small

motors spin very fast. |

|

|

InterfaceThe H7001 has 2 power lines (3 to 5V) and 2 signal out lines, TTL and CMOS compatible. The light emitting LED needs an important current (20 to 100 mA), but this current can be switched on by the microcontroller 10 microseconds before reading the H7001 outputs, and switched off immediately after. The average power consumption is hence very low. |

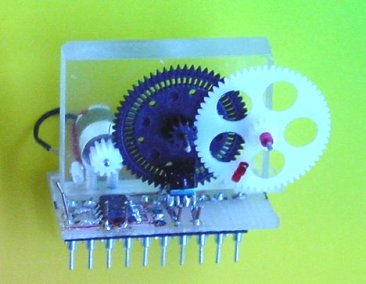

Examples of design |

|

|

|

Several years ago, the SFH910 was sold with a 30mm 96 slots coding wheel.

Several dual channels optical encoders exist (Hewlett Packard ). Hall

encoders are available from Allegro, but it is not easy to get the magnets

that will give precise square waves, if they are required.

Mechanical encoders are easy to get from many sources, but they have an

important friction and bounces. Let us mention also the many industrial,

fully packaged optical encoders, high resolution and a high price.

|

CH-1092 Belmont/Lausanne |